Advanced NDT Interpretation & Evaluation

With our owned advanced technology equipment, we aim to act as a trustworthy and valuable partner, in the Evaluation and Appraisal of the Integrity and overall condition of complex structural systems and components.

Our Advanced NDT services are addressed, but not limited to the following sectors:

- Oil & Gas industry, including Refineries, transport oil and gas Pipe-Lines, rotating and reciprocating machinery, Tank Farms, etc.

- Power Generation industry, including coolant systems, steam turbines, gas turbines, etc.

- Marine Constructions and Offshore Facilities, including Port facilities, Platforms, Shipyards, maritime vessels, etc.

- Civil engineering structures, including buildings, Touristic infrastructure, Cranes and Lifting Equipment, etc.

- Renewable energy industry, including wind turbines, hydroelectric generators, photo-voltaic panels, concentrated solar receivers, etc.

- Transport, including rail infrastructure, rolling stock, aircraft, trucks, etc.

- Food Industry, Processes and Chemical Plants.

The Advanced NDT service portfolio offered by SWISS APPROVAL includes:

- Semi-automatic and Automatic A/B/C/S Scans with Phased Arrays with TFM imaging, for a variety of structural components including pipes, castings, rails, crossings, wind turbine towers, pressure vessels, storage tanks, etc.

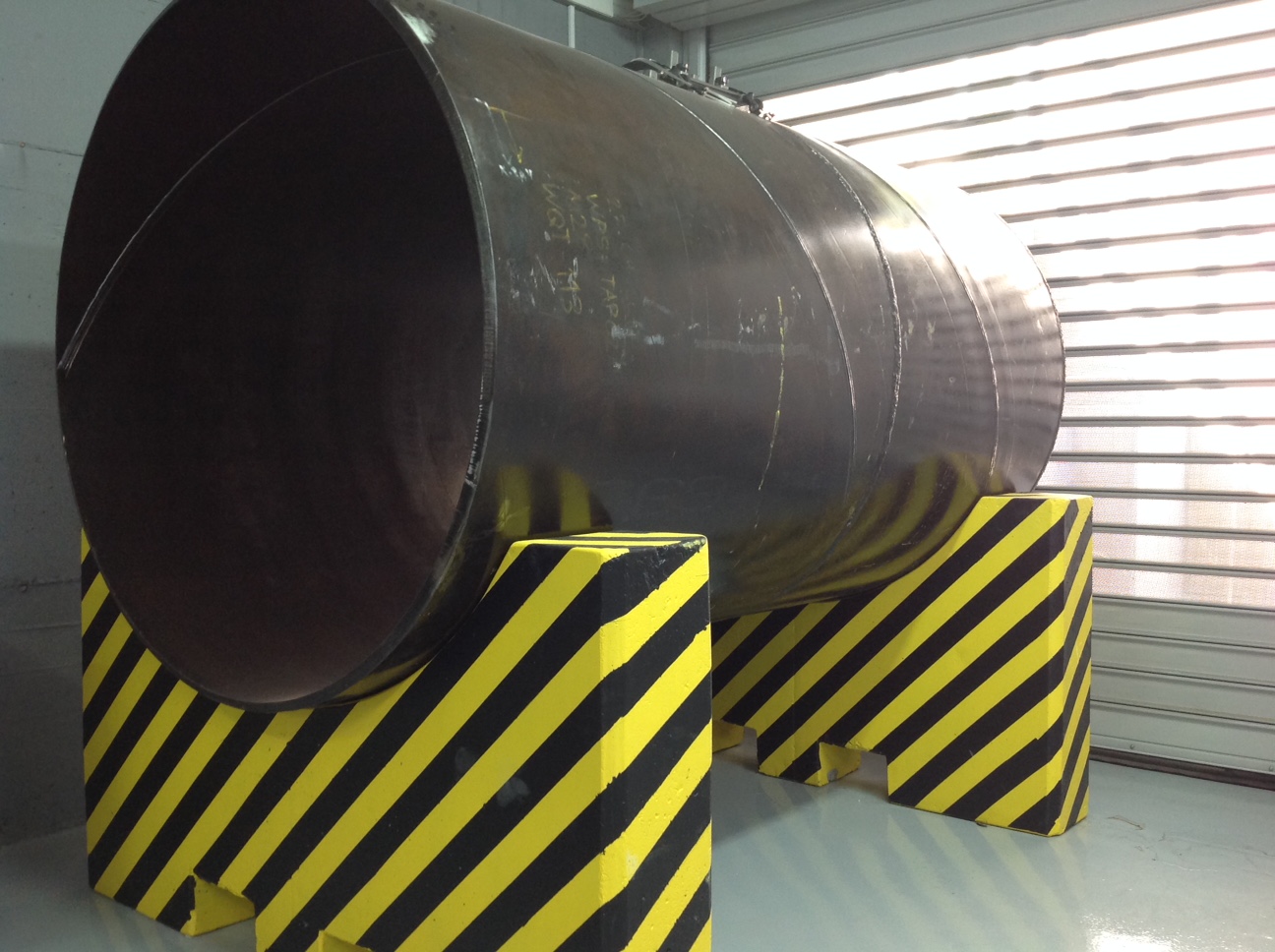

- Creeping Waves, for tubes of all diameters, and any kind of vessels inspection.

- Limited Geometric Space Inspection of Welds with use of specific Scanner Probes. For Butt & Fillet Welds. Weld Point inspection included.

- Flanges Inspection on Line, using Phased Array / TFM imaging.

- Robotic Inspection and corrosion mapping, for surfaces of Vessels and Tanks.

- High Temperature thickness measurements, even at temperatures up to 1000°C.

- Pulsed Eddy Current [PEC]. With this method, we can measure rapidly and reliably components for structural degradation, including creep and micro-structural changes at temperatures up 600°C. The method can be implemented above the insulation / coating thanks to the use of pulses.

- MFL Scanning for bottom of TANKS. The method is mainly used, normally together with phased arrays on specific problems, for the assessment of the floor of ferrous storage Tanks. However, this particular inspection technique can be easily employed for the inspection of vessels and platforms.

- On Line Test Systems, for Safety Valves. Issue of Certificate upon successful results.

- Wire Rope Magnetic Inductive Inspection, according to European and International Standards For diameters ranging up to 40mm. Larger diameters up to 80 are also possible to inspect.

- IRIS, RFT, NFT, NFA, ECA, for the control of Heat Exchangers, including internal piping.

- Remote Visual Inspection (RVI), with the use of drones with built-in cameras, and infrared cameras to detect leakage, etc.

- Acoustic Emission monitoring for monitoring of complex structures, during normal operation or during hydro-static testing.

- Thermographic techniques for rapid inspection of complex constructions, using cameras with wide lens and high resolution of imaging.

- Guided UT, from 2 inches to 56 inches pipes Diameter. With Longitudinal and Torsional waves.

- Pipe Scan, with UT and Magnetic waves. Bilateral Scan of pipes in operation.

- Civil Constructions & Concrete Inspection, for assessment of infrastructures basement, and corrosion mapping / assessment of reinforcement steel. Static Analysis of any kind of structures within industries, based on the acquired data by advanced NDT technologies.